The pure steam generator is designed to produce high-quality clean steam using purified water as feed water and industrial steam as the heating source. This equipment is widely used in pharmaceutical manufacturing as well as food and cosmetic production lines for sterilizing pipelines, tanks, and other process equipment. The condensate from the produced pure steam meets the stringent requirements of the Chinese Pharmacopoeia (CP 2020), United States Pharmacopeia (USP 43), and European Pharmacopoeia (EP 10) for Water for Injection (WFI).

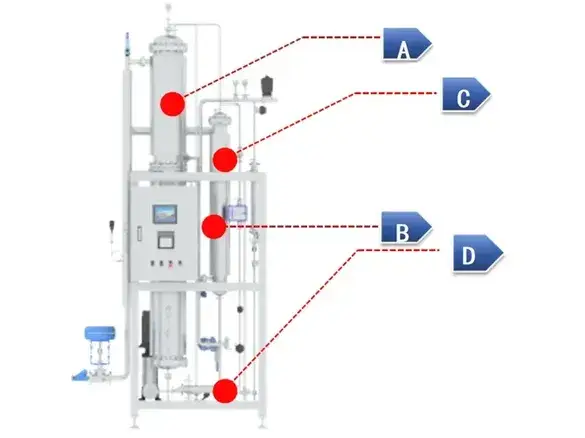

Purified feed water is pressurized by a multi-stage pump and first preheated in a pipeline condenser using waste heat. The water then passes through preheater 2 and preheater 1 for additional heat exchange before entering the evaporator. Inside the evaporator, a water distributor sprays the feed water along the inner wall of the heating tubes, forming a thin film that is rapidly vaporized by industrial steam.

The generated secondary steam, carrying fine water droplets, moves to the steam-water separation system. Through three stages of separation, the droplets are removed, producing ultra-clean pure steam suitable for pharmaceutical-grade sterilization and cleanroom applications.

| Model | Capacity (L/h) | Industrial Steam Consumption (L/h) | Feed Water Consumption (L/h) | Dimensions (mm) |

|

|

≥100 | 110 | 110 | 1200×800×2900 |

|

|

≥200 | 220 | 220 | 1400×1000×3350 |

|

|

≥300 | 330 | 330 | 1550×1100×3650 |

|

|

≥400 | 440 | 440 | 1500×1100×4100 |

|

|

≥500 | 550 | 550 | 1900×1310×3800 |

|

|

≥750 | 825 | 825 | 1900×1310×4100 |

|

|

≥1000 | 1100 | 1100 | 2000×1360×4500 |

|

|

≥1500 | 1650 | 1650 | 2400×1500×4800 |

|

|

≥2000 | 2200 | 2200 | 2400×1500×5100 |

Our pure steam generator uses purified water as feed water and industrial steam as the heating source to produce clean pure steam. The condensate meets the specifications for Water for Injection (WFI) as defined in the Chinese Pharmacopoeia (CP 2020), United States Pharmacopeia (USP 43), and European Pharmacopoeia (EP 10). It is fully suitable for sterilizing pharmaceutical production lines.

Our pure steam generator, constructed from SS316L stainless steel in all product-contact areas, produces clean, high-temperature pure steam ideal for disinfecting pipelines and equipment in the food service and catering industries.

The condensate produced by our pure steam generator complies with CP 2020, USP 43, and EP 10 standards for WFI. Its evaporator, preheater, and condenser feature a dual-tube sheet design, effectively preventing cross-contamination. This makes it well-suited for sterilization processes in cosmetic production lines.

Yes. Our pure steam generator converts feed water into ultra-clean steam through a three-stage separation process. The evaporator and preheaters are insulated with high-performance aluminum silicate blankets for system stability. An HMI + PLC fully automated control system provides precise monitoring and control of steam pressure and flow, ensuring consistent operation for biotech applications.

Yes. The system can rapidly ramp up from standby to full production capacity. Level control optimizes purified water usage, reducing energy waste. Additionally, preheaters utilize condensate from industrial steam for feed water preheating, enhancing overall energy efficiency.

Complete the form below to get customized recommendations based on your pharmaceutical water treatment systems application and compliance needs. Our technical team will contact you shortly with a suitable solution.