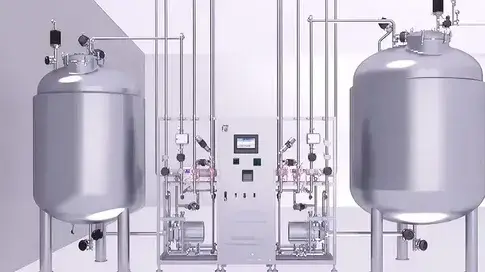

Purified water must be stored and distributed under strict hygienic conditions to maintain their quality until the point of use. Our storage and distribution system are carefully designed based on the layout of the production facility and the user’s preferred sterilization method. Following the principles outlined in GMP, ISPE guidelines, and FDA regulations, the system ensures safe water handling and minimal risk of contamination. The layout of our pharmaceutical grade purified water storage and distribution systems maximize the use of available space while maintaining easy access for maintenance and operation. High-quality hygienic piping and fittings are selected to eliminate dead legs and avoid contamination risks. The return loop is designed to maintain continuous circulation, preserving temperature and quality standards across the entire network. Every detail, from piping configuration to system control, supports user validation requirements and ensures reliable long-term operation.

Widely used in pharmaceutical manufacturing, medical facilities, and food production environments.

Note: Each pharmaceutical water system is custom-designed to meet the user requirement specification (URS) provided by the client. All photos and videos featured are from actual WEMAC projects.

Complete the form below to get customized recommendations based on your pharmaceutical water treatment systems application and compliance needs. Our technical team will contact you shortly with a suitable solution.